From all of us at Power Specialties, we wish you and yours a wonderful holiday season filled with unforgettable moments of happiness and laughter.

Here's to a prosperous and successful New Year for all.

A blog intended to educate and inform those interested in industrial control instrumentation and process control equipment. Weekly posts on various subjects ranging from pressure / temperature / level and flow instruments, control valves, analytical instruments, drives and actuators, recorders, and process weighing.

For more information, visit the Power Specialties website or call (816) 353-6550

Excellent Airflow Measurement & Control Technical Reference Material

While the document below is written as the Air Monitor's Industrial Product Catalog, it is also EXCELLENT TECHNICAL REFERENCE manual for a wide variety of airflow technical data.

While the document below is written as the Air Monitor's Industrial Product Catalog, it is also EXCELLENT TECHNICAL REFERENCE manual for a wide variety of airflow technical data.

This document includes:

- Standards for quantity and positioning of individual velocity measurements from ASHRAE, AMCA, and the Code of Federal Regulations.

- Important airflow conversion charts.

- Suggested specifications.

- Volumes of products and application information.

Air Monitor has been delivering airflow measurement solutions since 1970 and is the premier solutions provider for Industrial Process and Power Generation markets with expertise in differential pressure and thermal dispersion measurement technologies.

We at Power Specialties hope you find this document helpful. Please call us at (816) 353-6550 with any airflow question or application you may have.

K-TORK Actuators + Controls by Rotork

|

| K-TORK pneumatic actuators by Rotork |

K-TORK Actuators + Controls are versatile, modular and available in both double-acting and spring-return models. They are used to operate ball, butterfly or plug valves, and other 90-degree or less rotating mechanisms.

K-TORK Actuators + Controls represents the future of valve automation. The vane actuator is a ‘True Rotary’ actuator that does not require the conversion of a linear motion to a rotary motion. The result is a simple, highly accurate and reliable quarter-turn pneumatic actuator that is specified for the most demanding process flow control applications.

For more information about K-TORK contact Power Specialties online at http://www.powerspecialties.com or call (816) 353-6550.

Smart Gas Transmission Pipe Using Fiber Optic Sensing Technology

Fiber optic sensing technology, referred to as "Smart Sensor Technology" is available for above ground and buried pipelines, with sensitivity and performance appropriate for each type or combined above and below ground installations.

The modular hardware and software developed by Hawk Measurement Systems is unique in the world and has world leading specifications and software development for false positive minimization and maximum flexibility for specific in-situ customer needs.

The Smart Sensor Technology monitors:

The modular hardware and software developed by Hawk Measurement Systems is unique in the world and has world leading specifications and software development for false positive minimization and maximum flexibility for specific in-situ customer needs.

The Smart Sensor Technology monitors:

- Sound / Vibration

- Temperature / Vibration

- Temperature Only

- Strain Only

- Temperature / Vibration / Strain / Sound

See the presentation below for more detail. For more information contact Power Specialties at (816) 353-6550 or visit http://www.powerspecialties.com.

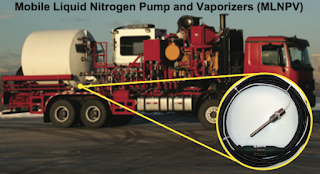

Innovative Sensor Design for Mobile Liquid Nitrogen Pump & Vaporizers (MLNPV)

|

| MLNPV Sensor Location |

Reprinted with permission from REOTEMP

Background

MLNPV's are used to pump nitrogen gas into natural gas wells and oil wells. Gas is pumped into the wells to purge remaining fossil fuels which may be imbedded in well bores, slurries, and bedrock. The purged fuels can then be used for commercial use.

Problem:

The MLNPV's require a variety of sensors to monitor internal components including: the liquid nitrogen tank, heat exchanger (used to convert liquid nitrogen to gas), and the pump. Temperature sensors are especially critical, since they are used to ensure safe, efficient operations.

The MLNPV's were originally outfitted with a gas actuated thermometer which had 30ft of capillary running from the sensor to the dial face located in the control box. The thermometer was subjected to a combination of extreme cold weather and continuous shock/vibration during operation and from traveling over unpaved, off-road paths and long highway drives. This harsh combination lead to continual failures in the field, increasing maintenance costs, downtime, and frustration for the manufacturer as well as the end user.

- Extreme sensor temperatures to -325F

- Ambient temperatures as low as -50F

- Continuous vibration & shock

- Harsh environment: oil, water, mud

The environment and harsh conditions required a sensor that would be extremely robust and still meet the customer's expectations of high accuracy, quick response time, and long life span.

Solution:

A prototype sensor they believed would meet all of the customers requirements. REOTEMP's design included heavy-duty mil-spec electrical connectors and plastic over-molding to prevent wire damage.

The sensor was put into action and performed extremely well:

- Able to withstand harsh environment: extreme temperature, oil, water, mud

- Improved accuracy

- Reduced lead time (to a couple of days)

- Lowered cost (by roughly 1/2)

For more information about REOTEMP Instruments, visit http://www.powerspecialties.com or call (816) 353-6550.

Dynamic Compensation for Static Pressure Effects in Differential Pressure Measurement

|

| Yokogawa DPharp |

Yokogawa Corporation has developed a means to dynamically compensate for static pressure effects in field measurements. The brief technical presentation below will help you understand how static pressure effects can impact your field measurements, as well as how Yokogawa’s Real-time Dynamic Compensation works to offset its impact.

More detailed product and application information is available from your Yokogawa specialist.

Labels:

differential pressure,

DPharp,

EJA,

EJX,

Instrumentation,

Iowa,

Kansas,

Missouri,

Nebraska,

process control,

Yokogawa

Improve Your Operations: Partner with Power Specialties

And now for a little harmless self-promotion ...

Resistance Thermometer Sensor and Thermocouple Data Collection

Resistance thermometer sensors (RTSs) and thermocouples are the temperature sensors most widely used in industrial temperature measurement. They have the advantages of simple construction and ease of use, making for convenience in measurement.

However, if correct application methods based on the proper standards are not followed, highly accurate measurements cannot be expected.

This document is a compendium of the basic data relating to resistance thermometer sensors and thermocouples. *This second edition reflects IEC and JIS revisions (thermocouples) of July 1995. We hope that this document will aid you in comparing the various underlying standards from an international viewpoint, and in deciding which standards to follow.

This document also provides information on vital parameters such as operating temperature ranges and tolerances.

However, if correct application methods based on the proper standards are not followed, highly accurate measurements cannot be expected.

This document is a compendium of the basic data relating to resistance thermometer sensors and thermocouples. *This second edition reflects IEC and JIS revisions (thermocouples) of July 1995. We hope that this document will aid you in comparing the various underlying standards from an international viewpoint, and in deciding which standards to follow.

This document also provides information on vital parameters such as operating temperature ranges and tolerances.

Tank Level, Interface Level and Temperature Monitoring in a Single Instrument

|

| MTS level transmitters |

Accuracy in detecting the interface is important. Imagine if you were refining oil and had a large tank of crude oil contaminated with water. Knowing where the water layer would be extremely important so it can be separated.

This video provides a quick visual understanding of interface. The instruments shown in the video (from MTS Sensors) are capable of providing accurate tank level measurement, interface level measurement, and also provides temperature measurement.

For more information on level measurement visit http://www.powerspecialties.com or call (816) 353-6550.

Type K Vane Actuator Provides Long Term Solution for Tough Power Plant Application

|

| Rotork K-TORK vane type valve actuators on bottom ash spray valve control. |

High-pressure spray water is used to sluice bottom ash and pyrites from the boilers’ hopper bottoms and to carry the ash out of the plant. The valves used are typically ANSI Class 300 double-offset high-performance butterfly designs ranging in size from 3” to 12”, automated with double-acting actuators. They cycle from four to ten times per day and discharge to atmosphere, creating a very high pressure drop. The flow media is re-circulated ash water that is abrasive and flows at pressures between 400 and 500psi.

In many power plants around the world, K-TORK actuators have provided over 10 years of maintenance-free service whilst preserving the life of the valves and valve seats in these arduous duties.

Among the challenges, it is imperative that the valves close fully and with zero leakage in a high pressure drop state. If the valve disc moves even slightly from the seat, the abrasive, high-pressure water will “wire-draw” or cut the butterfly valve seat. Traditionally, rack-and-pinion or scotch-yoke actuators have been used in this application, but “slop” or hysteresis in the rotary-to-linear conversion allows for the pressure in the pipe to move the disc from the seat, often causing premature failure of the valve after a period of only three to twelve months.

The problem becomes more acute when multiple valves are leaking, lowering the available back-pressure at the header, which makes it difficult or impossible to move the ash from the boiler.

When assembled to the valve with a ‘No-Play’ coupling, the K-TORK actuator has zero lost motion, “slop” or hysteresis. The one-piece vane and drive shaft cannot be back-driven and will hold the disc of the valve firmly in place.

Additional challenges include the location of the valves on a manifold at the bottom of the boiler where space is critical and plant air can be poor quality. K-TORK provides the smallest torque-to-size ratio and the double-opposed lip seal design is forgiving to dirty or contaminated air.

Also, the low-friction performance of K-TORK provides a speed-controlled, smooth valve operation, eliminating the risk of water hammer created by the high pressure drop.

Finally, longer run time between shutdowns demands increased reliability from the equipment in these critical applications. In particular, as the number of plant maintenance personnel has decreased, actuators that reduce maintenance (seal replacement) time and work orders have a direct payback to the owner, especially when valve life can be significantly increased through improved actuator performance.

Labels:

Actuation,

bottom ash,

Iowa,

K-Tork,

Kansas,

Missouri,

Nebraska,

power generation,

Rotork,

Valve Actuator

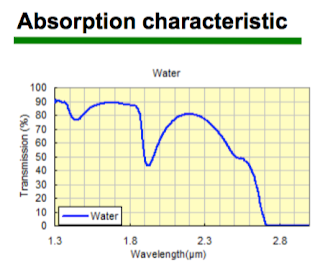

Moisture Measurement for Incinerator Ash

Incinerator ash needs extensive moisture control; ash would be scattered around with very low moisture, while excess moisture would cost more (to transport).

CHINO's IM series can measure the moisture of the ash placed on the running conveyor belt quickly and without touching the material. As the results, the amount of water mixed into the ash after the burning process can be controlled properly and easily.

Because there is dust around the installation area, IRMA should be kept inside an insulated cooling box, with air purged. Usually the moisture of incinerator ash can be measured within 0 to 30 %( ±0.5% accuracy).

IM Series is equipped w/ 4-20mA Analog output which can be easily incorporated with existing process control systems.

- General moisture unit Model : IRMA1100S

- Air purge hood Model : IR-WEA

- Calibration checker plate Model : IR-WEB

Install at 90 deg. to measure. Strongly recommend to use air purge AND insulated cooling box to prevent lenses from dusty ash. Some samples are dark in color and not in good condition to reflect well. To get better results, place a sample in a stable condition, such as measured on leveled surface, and with proper distance; eliminating external lights, or preventing from dust, as possible. Also, it is highly recommended to run zero calibration by simply using IR-WEB every 3 months.

Basic Sample Test for Moisture

- Prepare samples with various moisture content

- Show each sample to IRMA and record absorption level

- As conducting step-2, determine moisture level with your reference instrument

- Put all data points on a X/Y graph and see if there’s a correlation

Note: Reference instrument may vary depending on the method

(by volume or weight).

(by volume or weight).

For more information on any industrial moisture analysis, contact:

Power Specialties. Inc.

www.powerspecialties.com

9118 E. 72nd Terrace

Raytown, MO 64133

Toll Free: (800) 432-6550

Phone: (816) 353-6550

Fax: (816) 353-1740

YHC5150X FieldMate Handheld Communicator

|

| YHC5150X |

The YHC5150X FieldMate Handheld Communicator is the latest HART® Communicator from Yokogawa. All HART® field devices can be configured, polled, and trimmed utilizing a Windows Embedded CE™ based system for faster processing and greater storage capacity. All options are standard and no subscription is required. The YHC5150X is a full function, DD Direct, HART® Communicator supporting universal, common practice, and device specific commands for commissioning, configuration, and maintenance operations.

A short listing of some of the more prominent features that make the YHC5150X a powerful universal HART communicator include:

- Reads manufacturers' DDs in their native format without the need for translations

- HART®-compliant modem communicates with any registered or unregistered HART® Device

- Features an ergonomic, handheld design

- Enhanced 4.3" diagonal anti-glare touchscreen with color graphic display (no stylus required)

- Full QWERTY keyboard for commissioning new transmitters

- On-Demand Help Menus and teachable device-specific short cuts

- More than twice the battery capacity of any handheld communicator

- Manage device information through PC connection

The video below provides additional detail and an overview of the product in action. More information on the HART Communicator, as well as other innovative products to improve productivity and effectiveness, is available from a product specialist.

Easy Damper Drive Replacement on Steam Turbines

|

| 3 day damper drive replacement and turn-around. |

The equipment selected to upgrade the old actuators was Rotork Type K damper drives, which provide a direct ‘drop-in-place’ replacement that exactly matches the existing damper drive footprint and output shaft location. Duplication of the existing drive’s dimensions simplifies the installation, enabling the upgrade to be swiftly completed in a matter of hours.

Type K damper drives incorporate vane type actuators that offer high speed full stroke capabilities of less than 5 seconds, combined with accurate and responsive positioning. The rugged construction is designed to withstand the harsh environments associated with power stations and combustion plants.

Once the two Type K pedestal mounted damper drive units had been delivered, installation of both units was performed by engineers from Rotork Site Services within three days.

Days one and two were taken up with the removal of the old equipment and the installation of new, enabling commissioning, testing and hand-over to be completed during day three.

For more information on Rotork Type K Damper Drives, visit this link or call Power Specialties at (816) 353-6550.

A Guide to Safe Electronic Weighing in Hazardous Locations

|

| Process weighing (BLH Nobel) |

For more information visit this link, or contact:

Power Specialties, Inc.

www.powerspecialties.com | (816) 353-6550

Thermal Mass Flowmeters for "Green Completions" in Oil & Gas Production

|

| Thermal Mass Flowmeter (Courtesy of Fox ThermalInstruments) |

Not only is this technology good for the environment, it is also provides economic benefits to the operators. Whereas open pits release a significant amount of combustion emissions and VOCs into the atmosphere, and flaring produces significant amounts of combustion emissions, green completion technology uses closed storage and vapor recovery. The methane and hydrocarbons are recovered and fed back into the system as a product for sale, or are recovered to power equipment and machinery on-site for additional cost savings.

Thermal mass flow meter applications are abundant. Used primarily to measure the flow of gases from the outlet of the separator tanks or to monitor fuel gas usage, there are also additional applications on the various pieces of well-site equipment.

For more information on applying thermal mass flowmeters in oil and gas applications, contact:

Power Specialties, Inc.

9118 E. 72nd Terrace

Raytown, MO 64133

Toll Free: (800) 432-6550

Phone: (816) 353-6550

www.powerspecialties.com

Rotating the Control Head on a Yokogawa ADMAG AXF Magnetic Flowmeter

|

| Yokogawa AXF magnetic flowmeter |

The ADMAG AXF is the magnetic flowmeter which has adopted the proven Dual Frequency Excitation. Moreover, the Enhanced Dual Frequency Excitation has been newly added to tackle more severe applications.

The AXF has user-friendly functions; such as an electrode adhesion level diagnosis function, infra-red switches which can be used for setting parameters without opening the case cover, ability to change the direction of electrical connection on the site.

Based on FOUNDATION™ fieldbus specifications, AXF Fieldbus models offer more flexible instrumentation through a higher level communication capability and propose the cost reduction by multi-drop wirings with less cables.

This video demonstrates how to rotate the control head in the event it is oriented in the wrong direction.

Acoustic Wave Technology for Industrial Level Applications

|

| Acoustic wave level sensor by Hawk Measurement |

The transmission of high powered acoustic waves ensures minimal losses through the environment where the sensor is located. Due to the high powered emitted pulse, any losses have far less effect than would be experienced by traditional ultrasonic devices. More energy is transmitted hence more energy is returned. Advanced receiver circuitry is designed to identify and monitor low level return signals even when noise levels are high. The measured signal is temperature compensated to provide maximum accuracy to the outputs and display.

Applications

Level Measurement - Waste water/water:

River level, wet wells, inlet screens, tanks, sumps, pump stations, water towers, dams, basin levels, chemical storage, etc.

Level Measurement - Mining:

Crushers, surge bins, ore passes, conveyor profile, blocked chute, stockpile, stackers, reclaimers, storage silos etc.

Level Measurement - Power Stations:

Boiler bunkers, raw coal bunkers, ash pits, fly ash silos, etc.

Others:

Food, cement, plastics, grain, chemicals, paper, irrigation, quarries

The Truly Universal Approach to Gas Detection. Design, Implementation and Maintenance

|

| Truly Universal Approach to Gas Detection |

Reprinted with permission from an article titled

Executive Summary

Protecting your people and your physical plant, while ensuring business continuity, are the most important functions of a fixed gas detection solution. Engineering a reliable, high-performance system that makes it easier and more cost effective to meet this challenge is the driving force behind a truly universal approach to gas detection.

This white paper is about the evolution and benefits of designing, implementing and maintaining a truly universal approach to gas detection. Our intention is to help you use this information, based on “universal truths,” to evaluate your current system and project the impact of next-generation gas detection on your organization’s safety and productivity in a global economy.

Introduction

Introduction

In a global economy, the challenges to personal safety, productivity, and business continuity are magnified. Companies in a wide range of industries, where the presence of combustible and toxic gases are a way of life, must continue to evaluate their gas detection systems or pay the price on many levels. This evaluation must consider a number of factors that can enhance safety, while streamlining installation and minimizing maintenance – in the present and the future. That’s what constitutes a truly universal solution.

Fixed Gas Detection with Legacy Technology/Instruments

Before we look ahead and evaluate a truly universal approach, it’s important to take a look at how gas detection is done with legacy technology today…

- a single detector is paired and tested with a single sensor, detecting only a single combustible or toxic gas;

- adopting new, advanced digital communication protocols necessitates replacing existing systems with new detectors and/or new sensors;

- unique certification requirements for different devices and regions complicate the ability to engage in business as a company expands its operations globally; • more points mean more maintenance and associated costs;

- a field technician’s toolbox is packed with multiple sensors, detector heads and accessories from multiple manufacturers, requiring major inventory investment;

- a large workforce with specialized knowledge is needed to address specific installation and service requirements; and multiple manuals, covering many different product lines, only complicate installation and impede productivity;

Call it a paradigm shift in response to customer needs. Today, there is an increasing call for higher levels of safety, performance, standardization, economies of scale, ease of use, and overall accountability. Meeting these needs and adding value to the customer experience begins with re-thinking fixed gas detection engineering.

Engineering a universal gas detection system provides its own set of challenges. But these challenges are being met and needs are being fulfilled. As you position your company to leverage a truly universal gas detection solution, you must evaluate where you are and where you need to be. The following exploration of legacy systems used in the field today and truly universal characteristics of next-generation gas detection instruments should aid in your evaluation.

One to Many

One to Many

- Legacy System: A single detector is paired with—and tested with—a single sensor, accommodating only a small number of combustible or toxic gases.

- Truly Universal System: A single gas detector accommodates multiple sensors, allowing you to detect multiple types of gases in one location. Working within the same device footprint the transmitter is designed to support different sensing technologies: combustible gas sensing with infrared and catalytic bead sensors and electrochemical and metal oxide semiconductor sensors for toxic gases. Using equally smart sensor technology allows the construction of sensors with multiple ranges in the same package which in turn enables range invariant calibration. One instrument that can provide the capabilities of multiple instruments, and one sensor that can support multiple gas ranges provides valuable flexibility not available in legacy gas detection devices.

Communication Protocols

- Legacy System: Legacy systems have traditionally relied on analog signals for communication. This limits the transmission of advanced diagnostics data that ensures a safe plant environment. Adopting digital communication protocols necessitates installing new detectors and/or new sensors.

- Truly Universal System: As needs change and new communications protocols are required, universal transmitters are engineered to accept new plug-and-play communication boards. This multiprotocol innovation – wired or wireless (when industry appropriate) – means protocols can be added without replacing the transmitter as a plant’s communication requirements change. You’ll want to make sure your transmitter accommodates a wide range of communication protocols, including Modbus, HART, wireless HART and wireless ISA100.11A. This kind of flexibility is a key to a futureproof gas detection solution, and the transition from rigid, proprietary systems to standards-based, secure systems that accommodate growth and change.

Calibration and Maintenance

- Legacy System: Because of engineering constraints, sensor calibration must be performed in the field, where conditions are less than ideal and both safety and performance may be compromised.

- Truly Universal System: Accurate calibration is critical to satisfying both safety and performance requirements. It also impacts productivity when false alarms, due to inaccurate calibration, slow down – or even shut down – production. Imagine the consequences of an electrochemical sensor triggering an alarm that releases a blanket of foam. The cleanup costs alone can be staggering!

Next-generation gas detection enables a calibration-in the-lab scenario, providing a more controlled and safe environment for establishing gas sensor parameters. This is a significant innovation, especially with legacy cat bead sensors which required proper voltage adjustments at the point of detection. Additionally, the flexibility to calibrate an electrochemical sensor to a particular gas level and then make simple adjustments to the range later—without recalibrating the sensor to the new range—can offer significant efficiencies in sensor maintenance.

Through advanced engineering, a transmitter’s microprocessor can remember the type of sensor installed, as well as all calibration values. This built-in system of checks and balances virtually eliminates duplication of effort and the possibility of installing the wrong sensor.

Global Standards

- Legacy System: Global certification, especially when deploying a variety of detectors, can complicate and delay the ability to engage in business as your company expands its operations.

- Truly Universal System: Expanding the certification of a gas detector for global acceptance (including CSA, ATEX, IECEx, INMETRO, GOST-R, China Ex, A & C Tick, Marine Directive - Ship’s Wheel/ ABS and SIL 2 certified by a third party agency), plays a critical role in facilitating quick global adoption. The process of seeking global certifications can be further streamlined when a single gas detector is flexible enough to accommodate a wide range of toxic and combustible gases.

Cost of Ownership

- Legacy System: The presence of more points (i.e., detectors) means higher maintenance, more complexity and incremental costs associated with added cabling, junction boxes and wiring.

- Truly Universal System: Less is more – and better – when you can reduce the number of points in a gas detection system. One device consolidating three points has a positive ripple effect in terms of installation and maintenance. For instance, at a site with 45 points, accepted practice would include point-to-point wiring, using a Modbus communication protocol wired back to a central location or controller. But with a multi-head scenario, handling three points each, the number of detectors is reduced to 15 devices. This approach represents significant cost savings. In fact, using a single detector that consolidates three points, with a single relay board to control three alarms, totally eliminates a costly controller. Multiply this configuration times three for every three-head detector/multiple sensor configuration, and your cost of ownership is further reduced.

- Legacy System: Multiple manuals or the knowledge of many different product lines can slow the installation process and impede productivity.

- Truly Universal System: In today’s climate, it is becoming increasingly important to do more with a smaller, less specialized workforce. Truly universal engineering produces solutions that are simple to use with consistency in design making products intuitive, easy to learn and easy to use. This reduces installation time and increases productivity.

- Legacy System: Large inventories of sensors, detector heads and accessories demand a significant inventory investment.

- Truly Universal System: A field technician looks in his toolbox and sees fewer sensors, detectors and calibration adapters, as well as fewer accessories (like deluge guards and flow cells). Universal mounting kits simplify the process in new installations, while retrofits to existing installations are significantly more manageable. This simplification also minimizes lapses in safety due to human error.

Conclusion

Exploring a series of “universal truths” about next-generation fixed gas detection is a critical first step in evaluating how you protect your people and maintain the highest levels of productivity. Truly universal gas detection begins with a singularly flexible system, engineered to ensure accurate performance in a wide range of environments; considers current and future manufacturing plant environments; and plays a significant role in keeping costs under control in the face of global certification requirements and a changing workforce. How you use this insight will impact where, and how successfully you conduct business.

For more information contact:

Power Specialties, Inc.

9118 E. 72nd TerraceRaytown, MO 64133

Toll Free: (800) 432-6550

Phone: (816) 353-6550

Fax: (816) 353-1740

Yokogawa Data Acquisition Product Line Changes

| DX1000/DX2000 |

The model CX 2000 was discontinued at the end of February. It combined data acquisition, display, control, and networking in a single unit. A scaled down version, CX 1000 was previously discontinued. The company recommends possible replacements to include one or more of the following products:

- Advanced Application Temperature Controller UT75A

- Button Operated DX1000/DX2000

- General Purpose Temperature Controller UT35A/UT32A

- Mid-level Temperature Controller UT55A/UT52A

- TC10 Temperature Controller

- Touch Screen GX10/GX20

- US1000 Digital Indicating Controller

- UTAdvanced UT32A-D

- UTAdvanced UT32A-V/C/R

Whatever your data acquisition needs and challenges, the best solutions will result from combing your process expertise with the knowledge of a product specialist. Reach out to them and get results.

pH Measurements for Corn Mash Slurry (Liquefaction)

|

| Yokogawa pH / ORP Sensors |

Many Ethanol plants running today are using a combination style pH electrode with a non-flowing reference to measure pH in the Mash Slurry transfer line from the Mash slurry mix tank to cook. The Mash is being pumped out of the Mash Slurry tank is at approximately 82 °C and 2 to 4 bar (180 °F and 40 to 60 psig). The original pH electrode systems that were installed during plant construction are online retractable assemblies and are mounted in orientations from completely horizontal to completely vertical and everywhere in between.

The Problem

The combination probe that is being used will typically drift out of calibration very quickly. Also, the probe is damaged sometimes from excessive removal from the process. The reason this probe drifts out of calibration is due to the fact that the non-flowing reference system plugs and becomes fouled by the mash passing by it. pH measurements are only as good as the reference required to make this measurement. If the reference is not doing its job, the measurement electrode will drift.

Product Recommendations

Yokogawa manufactures a multi-probe holder called the FF20 – flow through fitting or the FS20, which is pH chamber assembly with 1⁄2” NPT process connections. With these holders we use a combination electrode, part number: SC21C-AGC55 for measurement and reference and a separate temperature sensor part number: SM60-T1. The Yokogawa electrode system works due to the fact that the SC21C-AGC55 combination probe uses a pressurized reference system. By using plant air regulated to a KCl reservoir, the SC21C-AGC55 utilizes a positive flowing reference that does not foul.

Plants using this system typically check the pH measurement against a grab sample and only make adjustments if the sample and the online measured values are more than 0.2 pH difference from one another. Typically, the system will not need daily or weekly calibrations. Most plants will pull the electrodes once a month for cleaning and calibration in a standard 4 and 7 buffer solutions.

|

| pH Probe Locations |

Installation Considerations

The Yokogawa pH system is not retractable from the process. It is usually best to put the Yokogawa pH electrodes in a by-pass or recirculation line that you can add isolation valves for isolating the probes from the process for maintenance and calibration. The probe assembly should be mounted downstream of the Slurry Tank transfer pump. Ideally it will be in a recirculation line going back into the tank or into the suction side of the slurry pump.

The picture below shows an installation that is actually flowing from left to right. The arrows indicate the direction of the mash flow through the recirculation line and back into the suction side of the pump. You will get an idea of the installation of the Yokogawa probes and the pressurized reference KCl reservoir from this picture. The reservoir pressure is typically set 1 to 2 psig above the slurry line pressure. The KCl reservoir will require refilling every 2-3 months for most applications.

The Yokogawa pH system is not retractable from the process. It is usually best to put the Yokogawa pH electrodes in a by-pass or recirculation line that you can add isolation valves for isolating the probes from the process for maintenance and calibration. The probe assembly should be mounted downstream of the Slurry Tank transfer pump. Ideally it will be in a recirculation line going back into the tank or into the suction side of the slurry pump.

The picture below shows an installation that is actually flowing from left to right. The arrows indicate the direction of the mash flow through the recirculation line and back into the suction side of the pump. You will get an idea of the installation of the Yokogawa probes and the pressurized reference KCl reservoir from this picture. The reservoir pressure is typically set 1 to 2 psig above the slurry line pressure. The KCl reservoir will require refilling every 2-3 months for most applications.

For more information contact:

9118 E. 72nd Terrace

Raytown, MO 64133

Toll Free: (800) 432-6550

Phone: (816) 353-6550

Fax: (816) 353-1740

Thermal Flowmeters with Constant Temperature Differential (∆T) Technology to Measure Mass Flow Rate of Air and Gases

Thermal flowmeters use a constant temperature differential (∆T) technology to measure mass flow rate of air and gases. The thermal mass flow sensor consists of two Resistance Temperature Detectors (RTD’s). The sensor elements are constructed of a reference grade platinum wire wound around ceramic mandrels that are inserted into stainless steel or Hastelloy tubes.

Thermal flowmeters use a constant temperature differential (∆T) technology to measure mass flow rate of air and gases. The thermal mass flow sensor consists of two Resistance Temperature Detectors (RTD’s). The sensor elements are constructed of a reference grade platinum wire wound around ceramic mandrels that are inserted into stainless steel or Hastelloy tubes. The reference RTD measures the gas temperature. The instrument electronics heat the mass flow sensor, or heated element, to a constant temperature and measures the cooling effect of the gas flow. The electrical power required to maintain a constant temperature differential is directly proportional to the gas mass flow rate. The microprocessor then linearizes this signal to deliver a linear 4 to 20mA signal.

The reference RTD measures the gas temperature. The instrument electronics heat the mass flow sensor, or heated element, to a constant temperature and measures the cooling effect of the gas flow. The electrical power required to maintain a constant temperature differential is directly proportional to the gas mass flow rate. The microprocessor then linearizes this signal to deliver a linear 4 to 20mA signal. One manufacturer, Fox Thermal Instruments, implements a technology they call the Power ProTM Sensor. Their sensor operates at a higher power level than other competitive thermal technologies, providing better response time and wider turndown. When compared to a typical differential pressure type flowmeter, as shown to the right, the Power ProTM sensor offers better low flow or low end sensitivity. The Power ProTM sensor also provides exceptional accuracy at high velocities - up to 50,000 SFPM air.

One manufacturer, Fox Thermal Instruments, implements a technology they call the Power ProTM Sensor. Their sensor operates at a higher power level than other competitive thermal technologies, providing better response time and wider turndown. When compared to a typical differential pressure type flowmeter, as shown to the right, the Power ProTM sensor offers better low flow or low end sensitivity. The Power ProTM sensor also provides exceptional accuracy at high velocities - up to 50,000 SFPM air.  The Fox DDC-SensorTM is a new state of the art sensor technology used in the Fox Model FT1 Thermal Gas Flow Meter. The DDC-SensorTM, a direct digitally controlled sensor that is interfaced directly to the FT1 microprocessor for more speed and programmability.

The Fox DDC-SensorTM is a new state of the art sensor technology used in the Fox Model FT1 Thermal Gas Flow Meter. The DDC-SensorTM, a direct digitally controlled sensor that is interfaced directly to the FT1 microprocessor for more speed and programmability. Like the PowerProTM Sensor, the DDC-SensorTM accurately responds to changes in process variables (gas flow rate, pressure, and temperature) which are used by the microprocessor to determine mass flow rate, totalized flow, and temperature.

In addition to measuring flow, the DDC-SensorTM provides a technology platform for calculating accurate gas correlations. The FT1 correlation algorithms allow the meter to be calibrated on a single gas in the factory while providing the user the ability to select other gases in the Gas-SelectXTM gas menu. Fox’s Model FT1 with its DDC-SensorTM and state-of-the-art correlation algorithms provide an accurate, multi-gas-capable thermal gas flow meter.

For more information on thermal flowmeters, contact:

Power Specialties, Inc.

9118 E. 72nd Terrace

Raytown, MO 64133

Toll Free: (800) 432-6550

Phone: (816) 353-6550

Fax: (816) 353-1740

Understanding Safety Integrity Levels (SIL)

|

| Safety Integrity Levels (SIL) |

|

| SIL-2 and SIL-3-rated toxic gas monitor |

Safety integrity level (or SIL) is often used to describe process safety requirements. However, there are often misconceptions or misunderstandings surrounding SIL. While the general subject, functional safety and SIL, can be highly technical, the general ideas can be distilled down to a few readily understandable concepts. A basic understanding is imperative to understand why it is important, what certification means, and the implications and benefits of that certification to the end user.

The following white paper, courtesy of Scott Safety, provides an excellent understanding of why SIL is important and how it is beneficial.

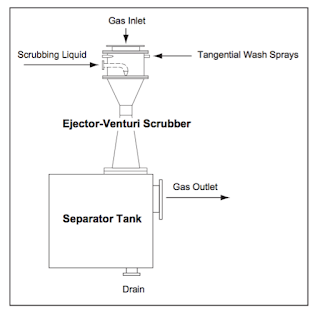

Maleic Anhydride Scrubbing Application

|

| S&K Ejector-Venturi Scrubber |

Background

Ejector Venturi Gas Scrubbers are very effective at removing noxious gases, particulates, odors, fumes and dusts from gas streams. Particulate contaminants are removed through impaction by the high velocity spray of scrubbing liquid. Gases and odors are eliminated through absorption and/or chemical reaction between the gases and scrubbing liquid. When properly matched to the application, these scrubbers, by their nature, are better able to cope with the high temperatures, heavy contaminant loads, and corrosive conditions often encountered.

Maleic Anhydride Scrubbing Challenges

|

| Custom Ejector-Venturi Scrubber |

The gas inlet and liquid inlet orientations are reversed such that the gas inlet is from the top and the liquid inlet from the side. This allows for the installation of tangential wash sprays just below the gas inlet to wash the walls and keep them wetted. As a result the dry/wet interface is eliminated in the body section where most plugging typically occurs.

Other applications utilizing same special design:

Other applications utilizing same special design:

- Removal of chlorinated silanes, which tend to form “sticky” gels during scrubbing

- Removal of elemental sulfur from sulfur holding tank vent exhausts

For more information on steam jet vacuum systems, steam jet heaters, exhausters and compressors, scrubber systems, desuperheaters, thermocompressors, eductors, or ejectors, contact:

Power Specialties, Inc.

9118 E. 72nd Terrace

Raytown, MO 64133

Toll Free: (800) 432-6550

Phone: (816) 353-6550

Fax: (816) 353-1740

Raytown, MO 64133

Toll Free: (800) 432-6550

Phone: (816) 353-6550

Fax: (816) 353-1740

The 2 Most Common Industrial Temperature Sensors

|

| Thermocouple & RTDs come in many shapes, styles, and configurations. |

A thermocouple is a temperature sensor that produces a micro-voltage from a phenomena called the Seebeck Effect. In simple terms, when the junction of two different (dissimilar) metals varies in temperature from a second junction (called the reference junction), a voltage is produced. When the reference junction temperature is known and maintained, the voltage produced by the sensing junction can be measured and directly applied to the change in the sensing junctions' temperature.

|

| Diagram of Type K thermocouple circuit |

As a general rule, industrial thermocouples can be made to withstand higher temperatures and come in a wider variety of thermocouple types. MgO thermocouples are flexible and have wider selection of measurement junction configurations. An MgO thermocouple consists of a thermocouple element encased in a metal sheath and hard-packed with magnesium oxide mineral insulation. Thermocouple sheaths are fully annealed and can be formed into different configurations (minimum bend radius is twice the outer diameter of the sheath). The measuring junction can also be sealed from the environment, reducing the potential for contamination issues.

A typical industrial thermocouple is constructed using an element inserted into a process/environment specific protection tube. In certain configurations, it may be possible to replace the element without removing the protection tube from the process. There are endless combinations of elements and tubes, and are also available separately as replacement parts.

|

| Standard industrial temperature sensor configuration (either thermocouple or RTD) |

RTD’s (resistance temperature detectors), are temperature sensors that measure a change in

resistance as the temperature of the RTD element changes. They are normally designed as a fine wire coiled around a bobbin (made of glass or ceramic), and inserted into a protective sheath. The can also be manufactured as a thin-film element with the pure metal deposited on a ceramic base much like a circuit on a circuit board.

|

| Coil wound RTD element (image courtesy of Wikipedia) |

RTDs are resistive devices, so lead wire resistance directly affects its accuracy. The error can be quite large, depending on the lead wire resistance (measured in ohms / foot).For example, an uncompensated 2-wire circuit using 30 gauge wires can have an error as high as 1.2°F per foot!Fortunately, there is a method to compensate for the lead wire resistance.

2-wire - One lead wire is connected to each end of the element. This arrangement is suitable for uses where the lead wire resistance may be considered as a constant in the circuit, or where changes in the lead wire resistance due to ambient temperature changes can be ignored.

3-wire - This is the most common of RTD configurations. One lead wire is connected to one end of the element and two lead wires are connected to the other end.The purpose of the third lead is to compensate for the lead wire resistance, thereby increasing accuracy.An instrument capable of utilizing a 3- wire RTD must be used to benefit from this configuration.

4-wire - The most accurate of the RTD configurations, this element uses two wires for each end of the element. Building on the 3-wire concept, compensation is made for the resistance in each lead wire, creating a highly-accurate temperature-measurement device for critical applications.An instrument capable of utilizing a 4-wire RTD must be used to benefit from this configuration.

For more information on temperature sensors, contact:

Power Specialties, Inc.

www.powerspecialties.com

9118 E. 72nd Terrace

Raytown, MO 64133

Toll Free: (800) 432-6550

Phone: (816) 353-6550

Fax: (816) 353-1740

Labels:

Iowa,

Kansas,

Missouri,

Nebraska,

Process Instruments,

Pyromation,

RTD,

sensor,

temperature,

thermocouple

Magnetostrictive Level Transmitters: How They Work

|

| Magnetostrictive level sensor (courtesy of MTS) |

Magnetostrictive level sensors provide continuous level measurement with high accuracy, and are very effective for use in a variety of liquids. In many applications they are used in conjunction with magnetic level gages (Mag Gage) to provide visual indication along with an analog or digital output.

Magnetostrictive level transmitters charge a magnetostrictive element with electric current. When the element's electromagnetic field intersects the float's magnetic field, a mechanical pulse is created. The pulse then travels back down the element at the speed of sound. Similar to ultrasonic or radar level transmitters, the distance is measured by time of flight, which corresponds to the distance from the sensor detecting the return pulse.

Here is a short video visually demonstrating the magnetostrictive principle:

Here is a more in-depth video demonstrating how a magnetostrictive level transmitter works:

Video created by Tony Kuphaldt and Bellingham Technical College and used here under Creative Commons Attribution 3.0 Unported license.

For more information on magnetostrictive level control, contact:

Power Specialties

9118 E. 72nd Terrace

Raytown, MO 64133

Toll Free: (800) 432-6550

Phone: (816) 353-6550

Fax: (816) 353-1740

Subscribe to:

Posts (Atom)