|

| S&K Ejector-Venturi Scrubber |

Background

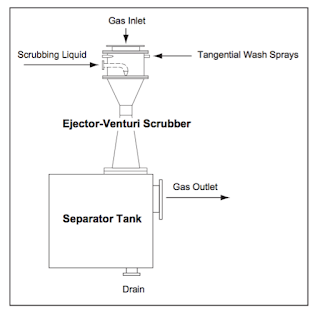

Ejector Venturi Gas Scrubbers are very effective at removing noxious gases, particulates, odors, fumes and dusts from gas streams. Particulate contaminants are removed through impaction by the high velocity spray of scrubbing liquid. Gases and odors are eliminated through absorption and/or chemical reaction between the gases and scrubbing liquid. When properly matched to the application, these scrubbers, by their nature, are better able to cope with the high temperatures, heavy contaminant loads, and corrosive conditions often encountered.

Maleic Anhydride Scrubbing Challenges

|

| Custom Ejector-Venturi Scrubber |

The gas inlet and liquid inlet orientations are reversed such that the gas inlet is from the top and the liquid inlet from the side. This allows for the installation of tangential wash sprays just below the gas inlet to wash the walls and keep them wetted. As a result the dry/wet interface is eliminated in the body section where most plugging typically occurs.

Other applications utilizing same special design:

Other applications utilizing same special design:

- Removal of chlorinated silanes, which tend to form “sticky” gels during scrubbing

- Removal of elemental sulfur from sulfur holding tank vent exhausts

For more information on steam jet vacuum systems, steam jet heaters, exhausters and compressors, scrubber systems, desuperheaters, thermocompressors, eductors, or ejectors, contact:

Power Specialties, Inc.

9118 E. 72nd Terrace

Raytown, MO 64133

Toll Free: (800) 432-6550

Phone: (816) 353-6550

Fax: (816) 353-1740

Raytown, MO 64133

Toll Free: (800) 432-6550

Phone: (816) 353-6550

Fax: (816) 353-1740