|

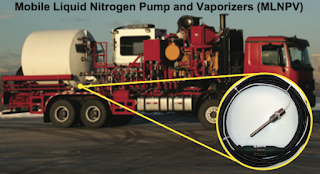

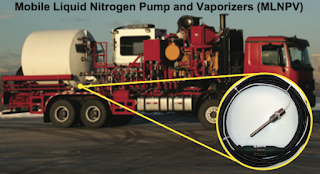

| MLNPV Sensor Location |

Reprinted with permission from REOTEMP

Background

MLNPV's are used to pump nitrogen gas into natural gas wells and oil wells. Gas is pumped into the wells to purge remaining fossil fuels which may be imbedded in well bores, slurries, and bedrock. The purged fuels can then be used for commercial use.

Problem:

The MLNPV's require a variety of sensors to monitor internal components including: the liquid nitrogen tank, heat exchanger (used to convert liquid nitrogen to gas), and the pump. Temperature sensors are especially critical, since they are used to ensure safe, efficient operations.

The MLNPV's were originally outfitted with a gas actuated thermometer which had 30ft of capillary running from the sensor to the dial face located in the control box. The thermometer was subjected to a combination of extreme cold weather and continuous shock/vibration during operation and from traveling over unpaved, off-road paths and long highway drives. This harsh combination lead to continual failures in the field, increasing maintenance costs, downtime, and frustration for the manufacturer as well as the end user.

- Extreme sensor temperatures to -325F

- Ambient temperatures as low as -50F

- Continuous vibration & shock

- Harsh environment: oil, water, mud

Considerations:

The environment and harsh conditions required a sensor that would be extremely robust and still meet the customer's expectations of high accuracy, quick response time, and long life span.

Solution:

A prototype sensor they believed would meet all of the customers requirements.

REOTEMP's design included heavy-duty mil-spec electrical connectors and plastic over-molding to prevent wire damage.

The sensor was put into action and performed extremely well:

- Able to withstand harsh environment: extreme temperature, oil, water, mud

- Improved accuracy

- Reduced lead time (to a couple of days)

- Lowered cost (by roughly 1/2)

For more information about

REOTEMP Instruments, visit

http://www.powerspecialties.com or call (816) 353-6550.