|

| Accuracy and consistency of web tension is critical. |

One typical problem occurs when the nip force is controlled by measuring the pressures in the cylinders. Because the cylinders are mounted some distance away from the spool, where the nip force is actually generated, the friction that arises in the machine reduces the accuracy of the measurement results. As the mechanical components in cylinders become worn, this problem grows and the inaccuracy of measurements increases. If you do not have force control on both sides, and do not have control over the prevailing conditions for each reel, the nip forces will lack repeatability. This increases the risk of varying density and wrinkle formation, both when changing reels, and during winding where paper breaks may also occur. When lowering the spool from the primary arm to the secondary arm, changes may occur in the lowering speed, and misalignment between the reels may also result in varying density, wrinkles, and paper breaks.

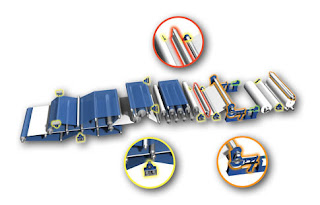

One solution from BLH Nobel is based on mounting load cells directly at the point of force application, as well as on the position sensors in each cylinder. The load cells are therefore installed in the primary arm and secondary arm, and in the spool clamp. This allows us to measure values in real time, which means that we know the actual forces in the critical transfer from the primary to the secondary arm. Acceleration speed and force can then be adjusted by positioning cylinders that are controlled by means of software.

By adopting load cells, paper reels of the right density, with wrinkle free paper, and less paper breaks are the outcome. In a typical mill with 3 to 4 percent of the jumbo role being rejected due to wrinkling, using load cells reduced the waste to less than 0.5 percent.

For more information, visit Power Specialties at http://www.powerspecialties.com or call (816) 353-6550.