Incinerator ash needs extensive moisture control; ash would be scattered around with very low moisture, while excess moisture would cost more (to transport).

CHINO's IM series can measure the moisture of the ash placed on the running conveyor belt quickly and without touching the material. As the results, the amount of water mixed into the ash after the burning process can be controlled properly and easily.

Because there is dust around the installation area, IRMA should be kept inside an insulated cooling box, with air purged. Usually the moisture of incinerator ash can be measured within 0 to 30 %( ±0.5% accuracy).

IM Series is equipped w/ 4-20mA Analog output which can be easily incorporated with existing process control systems.

- General moisture unit Model : IRMA1100S

- Air purge hood Model : IR-WEA

- Calibration checker plate Model : IR-WEB

Install at 90 deg. to measure. Strongly recommend to use air purge AND insulated cooling box to prevent lenses from dusty ash. Some samples are dark in color and not in good condition to reflect well. To get better results, place a sample in a stable condition, such as measured on leveled surface, and with proper distance; eliminating external lights, or preventing from dust, as possible. Also, it is highly recommended to run zero calibration by simply using IR-WEB every 3 months.

Basic Sample Test for Moisture

- Prepare samples with various moisture content

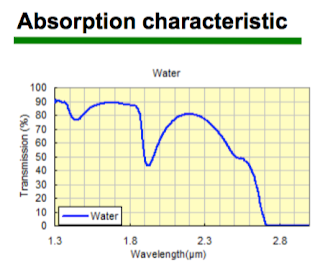

- Show each sample to IRMA and record absorption level

- As conducting step-2, determine moisture level with your reference instrument

- Put all data points on a X/Y graph and see if there’s a correlation

Note: Reference instrument may vary depending on the method

(by volume or weight).

(by volume or weight).

For more information on any industrial moisture analysis, contact:

Power Specialties. Inc.

www.powerspecialties.com

9118 E. 72nd Terrace

Raytown, MO 64133

Toll Free: (800) 432-6550

Phone: (816) 353-6550

Fax: (816) 353-1740