A blog intended to educate and inform those interested in industrial control instrumentation and process control equipment. Weekly posts on various subjects ranging from pressure / temperature / level and flow instruments, control valves, analytical instruments, drives and actuators, recorders, and process weighing.

For more information, visit the Power Specialties website or call (816) 353-6550

Happy New Year from Power Specialties

With 2017 coming to a close, all of us at Power Specialties wanted to reach out and send our best wishes to our customers, our vendors, and our friends! We hope that 2018 holds success and good fortune for all of you.

Moisture Measurement in Sugar Production

|

| Moisture detection in sugar production. |

The sugar industry processes sugar cane and sugar beets to manufacture edible sugar. To achieve high quality sugar, improve efficiency and keep production cost in check, moisture detectors are employed to deliver accurate moisture analysis during several stages of the process.

Typical processes are as follows;

Washing/Preparation/Extraction

Sugar cane:

- Milling with water, extracting raw juice -> purification

Sugar beet:

- Diffusing with hot water, extracting raw juice -> purification.

- Crystallized sugar after purification is called "raw sugar". Raw sugar is then dried and may be further refined before bagging for shipment.

CHINO's IM Series online system can measure moisture to maintain product consistency as well as energy efficiency at the following parts of the sugar manufacturing process.

Moisture measurement of "Bagasse" (fiber residue of the canes).

Moisture measurement of "Bagasse" (fiber residue of the canes).- 10% - 40% (Accuracy: +/- 0.5%)

- Bagasse is mainly used as a biofuel, renewable resource in the pulp, paper products and building materials.

- 30% - 70% (Accuracy: +/- 0.5%)

- Used cossettes are dried and sold as animal feed

- IM Series is equipped w/ 4-20mA analog output which can be easily incorporated with existing process control systems.

Labels:

Chino,

Instrumentation,

Iowa,

Kansas,

Missouri,

Moisture detection,

Nebraska,

sugar production

Schutte & Koerting Steam Jet Vacuum Systems

Steam Jet Ejectors are used in the chemical, petrochemical, pulp and paper, food, power, steel and allied industries in connection with such operations as filtration, distillation and evaporation, absorption, mixing, vacuum packaging, freeze drying, flash cooling, deaerating, dehydrating and degassing to name just a few. They will handle both condensable and non-condensable gases and vapors as well as mixtures of the two. Small amounts of solids or liquids will not adversely affect performance.

The principal feature of the Barometric Condenser is that injection water may be discharged through a tail pipe by gravity, without requiring a pump. The Barometric Condenser is employed in a variety of industries as an economical means of removing air, exhaust steam, and other vapors from vacuum equipment.

The principal feature of the Barometric Condenser is that injection water may be discharged through a tail pipe by gravity, without requiring a pump. The Barometric Condenser is employed in a variety of industries as an economical means of removing air, exhaust steam, and other vapors from vacuum equipment.

The video below provides and overview of the extensive capabilities Schutte & Koerting has in the engineering, design, and fabrication of steam jet vacuum systems.

Contact Power Specialties for Schutte & Koerting inquiries by calling (816) 353-6550 or visit https://www.powerspecialties.com.

Contact Power Specialties for Schutte & Koerting inquiries by calling (816) 353-6550 or visit https://www.powerspecialties.com.

Gas and Flame Detection: Custom Battery Backup Solution

|

| Scott toxic & flammable gas detection transmitter. |

A leading food and beverage company needed a battery back-up system for their extensive gas detection system in the event of power loss.

The Scott Safety integration team implemented a UPS battery back-up system to supply reserve power to over 300 gas detectors in the system for up to 24 hours in the event of a power loss, ensuring a safe environment.

The implemented Scott solution consisted of seven identical battery back-up systems. Each back-up system would support the corresponding controllers and transmitters associated with that system, building or process. Upon primary power loss, the custom battery backup was required to maintain full load of the assigned controllers and transmitters in a full alarm situation for 24 hours. The custom battery back-up system required a modular design so that the enclosures could be a standard manufactured product but assembled on-site. The UPS also provided system diagnostics that were tied into a PLC that was also provided to monitor the controllers’ fault alarms.

For more information on this solution, or any gas detection requirement, visit Power Specialities at https://www.powerspecialties.com or call (816) 353-6550.

For more information on this solution, or any gas detection requirement, visit Power Specialities at https://www.powerspecialties.com or call (816) 353-6550.

Combustion & Fired Heater Optimization: An Analytical Approach to Improving Safe & Efficient Operations

Combustion sources such as furnaces and red heaters play a critical role in the process industry. Unfortunately, combustion requires large amounts of fuel (gas, fuel oil). As a result, combustion efficiency directly influences the performance and operational costs of production facilities. However, efficiency is not the only concern. Compliance and safety are major challenges as well.

Download this eBook to read more on combustion and fired heater optimization and deploy an analytical approach to improving safe & efficient operations.

Download this eBook to read more on combustion and fired heater optimization and deploy an analytical approach to improving safe & efficient operations.

Alternatively, you view the embedded version below.

If you have questions, please call Power Specialties at (816) 353-6550 or fill out this online form.

Mounting Advice for the BLH Nobel KIS and KIM Load Cells

High-accuracy KIS and KIM load cells have several features that distinguish them from other load cells. They are easy to install and extremely accurate, even when subjected to dynamic process forces and severe environmental conditions. Due to their double cantilever design, they have a floating load point and are not affected by side forces up to 100%, making them excellent choices for applications subject to thermal expansion, vibrations and side force disturbances.

Understanding Differential Flow Elements

|

| Differential Pressure Loop Diagram (courtesy of Yokogawa) |

The differential flow meter, whether Venturi tube, flow nozzle, or orifice plate style, is an in line instrument that is installed between two pipe flanges.

The orifice plate flow meter is comprised the circular metal disc with a specific hole diameter that reduces the fluid flow in the pipe. Pressure taps are added on each side at the orifice plate to measure the pressure differential.

According to the Laws of Conservation of Energy, the fluid entering the pipe must equal the mass leaving the pipe during the same period of time. The velocity of the fluid leaving the orifice is greater than the velocity of the fluid entering the orifice. Applying Bernoulli's principle, the increased fluid velocity results in a decrease in pressure.

As the fluid flow rate increases through the pipe, back pressure on the incoming side increases due to the restriction of flow created by the orifice plate.

The pressure of the fluid at the downstream side at the orifice plate is less than the incoming side due to the accelerated flow.

With a known differential pressure and velocity of the fluid, the volume metric flow rate can be determined. The flow rate “Q”, of a fluid through an orifice plate increases in proportion to the square root the pressure difference on each side multiplied by the K factor. For example if the differential pressure increases by 14 PSI with the K factor of one, the flow rate is increased by 3.74.

Data Acquisition for Milk and Dairy Pasteurization

|

| Yokogawa Touch Screen GX10/GX20 |

Reprinted with permission from Yokogawa.

Introduction Pasteurization is a process that aims to reduce and destroy the number of viable pathogens/bacteria in the product so that the unwanted pathogen/bacteria does not cause harm to human health. Pasteurization is a critical process in a wide range of products such as: milk, cheese, juice and alcohol. Food and beverage manufacturers must demonstrate and ensure that products undergoing pasteurization meet the strict requirements of international standards so that the product is deemed safe for human consumption. Significant fines and penalties may be imposed if the pasteurization process is not followed.

Depending on the product, there are specific requirements on the temperature and amount of hold time required to ensure the product is safe. There are two main types of the pasteurization process:

Application

Pasteurization can be conducted as a batch or a continuous process. The most common process used for fluid milk is the continuous process. The milk is pumped from the raw milk silo to a holding tank that feeds into the continuous pasteurization system. The milk continuously flows from the tank through a series of thin plates that heat up the milk to the appropriate temperature. Once the milk is heated, it is sent into a “holding tube” that is set up to make sure the milk stays at the pasteurization temperature for the appropriate time before it flows through the cooling area of the pasteurizer. The cooled milk then flows to the rest of the processing line for packaging and bottling.

If the appropriate pasteurization temperature was not maintained at the outlet of the holding tube, then a divert valve opens to pass the milk back for reprocessing.

Typically, a paperless recorder is deployed to measure the temperature of the product (hot and cold) as well as the divert valve position. The operation of the divert valve is often triggered from the paperless recorder. It is imperative to record these variables to ensure the product is processed correctly through pasteurization. Additionally, the recorded data is often used for audit and traceability requirements.

Solution

Yokogawa’s best-in-class panel mount paperless recorders are fully integrated data acquisition and display stations with secure, built-in data storage and network connectivity. Panel-mount solutions are NEMA compliant and integrate the data acquisition equipment into a control panel. Yokogawa’s paperless recorder lineup meets the rigorous industry standards such as PMO, HTST and FDA 21CFRPart11.

- High Temperature Short Time (HTST): Product is forced between metal plates or pipes heated on the outside by hot water and product is heated to 72 °C (161 °F) for 15 seconds

- Ultra Heat Treating (UHT): Product is forced between metal plates or pipes heated on the outside by hot water and product is heated to 140 °C (284 °F) for 4 seconds

Application

Pasteurization can be conducted as a batch or a continuous process. The most common process used for fluid milk is the continuous process. The milk is pumped from the raw milk silo to a holding tank that feeds into the continuous pasteurization system. The milk continuously flows from the tank through a series of thin plates that heat up the milk to the appropriate temperature. Once the milk is heated, it is sent into a “holding tube” that is set up to make sure the milk stays at the pasteurization temperature for the appropriate time before it flows through the cooling area of the pasteurizer. The cooled milk then flows to the rest of the processing line for packaging and bottling.

If the appropriate pasteurization temperature was not maintained at the outlet of the holding tube, then a divert valve opens to pass the milk back for reprocessing.

Typically, a paperless recorder is deployed to measure the temperature of the product (hot and cold) as well as the divert valve position. The operation of the divert valve is often triggered from the paperless recorder. It is imperative to record these variables to ensure the product is processed correctly through pasteurization. Additionally, the recorded data is often used for audit and traceability requirements.

Solution

Yokogawa’s best-in-class panel mount paperless recorders are fully integrated data acquisition and display stations with secure, built-in data storage and network connectivity. Panel-mount solutions are NEMA compliant and integrate the data acquisition equipment into a control panel. Yokogawa’s paperless recorder lineup meets the rigorous industry standards such as PMO, HTST and FDA 21CFRPart11.

For more information about Yokogawa products, contact:

Power Specialties, Inc.

Raytown, MO 64133

Toll Free: (800) 432-6550

Phone: (816) 353-6550

Fax: (816) 353-1740

Super-fast Changeout of Sanitary Temperature Sensor

|

| Diagram 1 |

Most existing temperature sensors have a threaded connection which would twist and tangle the extension wires when unthreaded for calibration. The only alternative to unthreading the connection is to disconnect the wires from the terminal. This wastes time and complicates the calibration process.

Manufacturer REOTEMP engineered a great solution. A product named "ReoClick" makes disconnecting and re-connecting the sensor from the process easy. With the click of a button, the temperature sensor is released from the the process, leaving the female adapter in place (see diagram 1). The sensor is then placed into a temperature bath for a quick calibration check and snapped back into service in a matter of seconds.

To make the design even better, REOTEMP incorporated a replaceable temperature element. The element can be easily removed when sensor replacement is eventually needed. This allows the customer to reuse their existing leadwire assembly, male insert, and female adapter (see diagram 2).

|

| Diagram 2 |

Along with those cost savings, the customer has avoided the usual headache associated with replacing a competitor’s elements: disconnecting wires, terminal blocks, reconnecting components, etc..

For more information about the ReoClick sanitary sensor, contact Power Specialties by visiting http://www.powerspecialties.com/article_54_REOTEMP.cfm or calling (816) 353-6550.

For more information about the ReoClick sanitary sensor, contact Power Specialties by visiting http://www.powerspecialties.com/article_54_REOTEMP.cfm or calling (816) 353-6550.

Labels:

BioTech,

Food and Beverage,

Iowa,

Kansas,

Missouri,

Nebraska,

Pharmaceutical,

RTD,

Sanitary,

Temperature sensor

The Pro's and Con's of Industrial Thermocouples and RTD's

Thermocouples and RTDs are the two most common type of industrial temperature sensors. A thermocouple is a temperature sensor that produces a micro-voltage relative to a temperature change which can be measured, conditioned, and amplified into a standard process signal. RTD’s are temperature sensors that measure a change in electrical resistance relative to the temperature surrounding the RTD element. Each have their advantages and disadvantages, and should be applied understanding their respective strengths and weaknesses.

RTD STRENGTHS:

RTD’s are commonly used in applications where repeatability and accuracy are important considerations. Properly constructed Platinum RTD’s have very repeatable resistance vs. temperature characteristics over time. If a process will be run at a specific temperature, the specific resistance of the RTD at that temperature can be determined in the laboratory and it will not vary significantly over time. RTD’s also allow for easier interchangeability since their original variation is much lower than that of thermocouples. For example, a Type K thermocouple used at 400°F has a standard limit of error of – 4°F. A 100 Ohm DIN, Grade B platinum RTD has an interchageability of – 2.2°F at this same temperature. RTD’s also can be used with standard instrumentation cable for connection to display or control equipment where thermocouples must have matching thermocouple wire to obtain an accurate measurement.

RTD WEAKNESSES:

In the same configuration, you can expect to pay from 4 to 10 times more for an RTD than for a base metal thermocouple. RTD’s are more expensive than thermocouples because there is more construction required to make the RTD including manufacture of the sensing element, the hooking up of extension wires and assembly of the sensor. RTD’s do not do as well as thermocouples in high vibration and mechanical shock environments due to the construction of the sensing element. RTD’s are also limited in temperature to approximately 1200°F where thermocouples can be used as high as 3100°F

THERMOCOUPLE STRENGTHS:

Thermocouples can be used to temperatures as high as 3100°F, generally cost less than RTD’s and they can be made smaller in size (down to approximately .020” dia) to allow for faster response to temperature. Thermocouples are also more durable than RTD’s and can therefore be used in high vibration and shock applications.

THERMOCOUPLE WEAKNESSES:

Thermocouples are less stable than RTD’s when exposed to moderate or high temperature conditions. In critical applications, thermocouples should be removed and tested under controlled conditions in order to verify performance. Thermocouple extension wire must be used in hooking up thermocouple sensors to thermocouple instrument or control equipment. Use of instrumentation wire (plated copper) will result in errors when ambient temperatures change.

SUMMARY:

Both thermocouples and RTD’s are useful instruments for determining process temperature. RTD’s provide higher accuracy than thermocouples in their temperature range because platinum is a more stable material than are most thermocouple materials. RTD’s also use standard instrumentation wire to connect to the measurement or control equipment.

Thermocouples are generally less expensive than RTD’s, they are more durable in high vibration or mechanical shock applications and are usable to higher temperatures. Thermocouples can be made smaller in size than most RTD’s so they can be formed to fit a particular application.

Contact Power Specialties by visiting http://www.powerspecialties.com or calling (816) 353-6550 for more information on temperature sensors.

RTD STRENGTHS:

RTD’s are commonly used in applications where repeatability and accuracy are important considerations. Properly constructed Platinum RTD’s have very repeatable resistance vs. temperature characteristics over time. If a process will be run at a specific temperature, the specific resistance of the RTD at that temperature can be determined in the laboratory and it will not vary significantly over time. RTD’s also allow for easier interchangeability since their original variation is much lower than that of thermocouples. For example, a Type K thermocouple used at 400°F has a standard limit of error of – 4°F. A 100 Ohm DIN, Grade B platinum RTD has an interchageability of – 2.2°F at this same temperature. RTD’s also can be used with standard instrumentation cable for connection to display or control equipment where thermocouples must have matching thermocouple wire to obtain an accurate measurement.

RTD WEAKNESSES:

In the same configuration, you can expect to pay from 4 to 10 times more for an RTD than for a base metal thermocouple. RTD’s are more expensive than thermocouples because there is more construction required to make the RTD including manufacture of the sensing element, the hooking up of extension wires and assembly of the sensor. RTD’s do not do as well as thermocouples in high vibration and mechanical shock environments due to the construction of the sensing element. RTD’s are also limited in temperature to approximately 1200°F where thermocouples can be used as high as 3100°F

THERMOCOUPLE STRENGTHS:

Thermocouples can be used to temperatures as high as 3100°F, generally cost less than RTD’s and they can be made smaller in size (down to approximately .020” dia) to allow for faster response to temperature. Thermocouples are also more durable than RTD’s and can therefore be used in high vibration and shock applications.

THERMOCOUPLE WEAKNESSES:

Thermocouples are less stable than RTD’s when exposed to moderate or high temperature conditions. In critical applications, thermocouples should be removed and tested under controlled conditions in order to verify performance. Thermocouple extension wire must be used in hooking up thermocouple sensors to thermocouple instrument or control equipment. Use of instrumentation wire (plated copper) will result in errors when ambient temperatures change.

SUMMARY:

Both thermocouples and RTD’s are useful instruments for determining process temperature. RTD’s provide higher accuracy than thermocouples in their temperature range because platinum is a more stable material than are most thermocouple materials. RTD’s also use standard instrumentation wire to connect to the measurement or control equipment.

Thermocouples are generally less expensive than RTD’s, they are more durable in high vibration or mechanical shock applications and are usable to higher temperatures. Thermocouples can be made smaller in size than most RTD’s so they can be formed to fit a particular application.

Contact Power Specialties by visiting http://www.powerspecialties.com or calling (816) 353-6550 for more information on temperature sensors.

Abstracted from Pyromation's White Paper "How to Select and Use the Right Temperature Sensor".

Understanding Overpressure and Overpressure Protection for Yokogawa DPharp EJX/EJA-E Series Transmitters

The video below demonstrates what overpressure is, how it effects pressure transmitters, and the mechanism Yokogawa deploys for overpressure protection for on their DPharp EJX/EJA-E series.

For more information on Yokogawa in Iowa, Kansas, Nebraska, or Missouri, contact Power Specialties by visiting http://www.powerspecialties.com or calling (816) 353-6550.

For more information on Yokogawa in Iowa, Kansas, Nebraska, or Missouri, contact Power Specialties by visiting http://www.powerspecialties.com or calling (816) 353-6550.

Type K Drives on Fly Ash Hopper Rotary Gates Save Vast Sums of Money and Time

|

| Type K drive on rotary gate. |

The application requires the pneumatic conveyors, operating under the precipitators, collect the flyash and push into collection bins using compressed air. In this application, pneumatic cylinders stroke full open, and closed, every 90-120 seconds, 24 hours a day, 7 days a week. That works out to around a grueling 720 cycles per day in a dirty, hot, and abrasive environment.

Fly ash is a term used for by-products of combustion and flue gases. Nearly half of this fly ash is reused for purposes such as dry wall production and cement mixes. Because of it's abrasive qualities and high temperatures, fly ash is a difficult material to handle reliably. It's handling takes a particularly tough toll on the valves and drives that control it's movement.

A decision was made to replace the air cylinders with Rotork Type K Series AH damper drives after a visit from a local sales engineer. Along with the new drives, high-cycle “no-play” linkage kits (that eliminate hysteresis) were retro-fitted to the existing ash hopper equipment.

After five years in service, there have been no failures. Not a single work order has been issued, no spare parts have been required, no seal kits installed and no units have been removed for servicing for any reason. Eliminating the cost of 50 air cylinders a year was quite significant, but even greater was the savings from the time and labor eliminated from their annual replacement.

For more information on this application, or on any damper drive application, visit Power Specialties at http://www.powerspecialties.com or call (816) 353-6550.

HAWK Fibre Optic System (FOS) Pipeline Leak Detection

New pipeline leak detection via infield fiber optic cable.

A new Fibre Optic-based Pipeline Leak Detection System informs of a leak occurrence and also provides accurate location of any potential leakage.

Multivariable single Fibre Optic System sensing detects change in stress / strain due to pipe bending or loss of support. It notes temperature changes caused by liquid or gas movement in pipe leaks. There is also sound and vibration detection from pipe leaks or third-party intrusions.

Systems combine multiple measured variables within one cable, such as sound, temperature, and vibration - to automatically cross reference and remove false signals.

The FOS-based solution seamlessly integrates into an existing digital control system or SCADA to alert operators through a variety of digital protocols.

Introduction to Industrial Continuous Level Control

|

| Magnetic level gauge combines float technology with level gauge simplicity (Hawk). |

A wide variety of technologies exist to measure the level of substances in a vessel, each exploiting a different principle of physics. This chapter explores the major level-measurement technologies in current use.

Level gauges

Level gauges are perhaps the simplest indicating instrument for liquid level in a vessel. They are often found in industrial level-measurement applications, even when another level-measuring instrument is present, to serve as a direct indicator for an operator to monitor in case there is doubt about the accuracy of the other instrument.

Float

Perhaps the simplest form of solid or liquid level measurement is with a float: a device that rides on the surface of the fluid or solid within the storage vessel. The float itself must be of substantially lesser density than the substance of interest, and it must not corrode or otherwise react with the substance.

|

| Hydrostatic level instrument to tank wall mounting (Yokogawa). |

A vertical column of fluid generates a pressure at the bottom of the column owing to the action of gravity on that fluid. The greater the vertical height of the fluid, the greater the pressure, all other factors being equal. This principle allows us to infer the level (height) of liquid in a vessel by pressure measurement.

Displacement

Displacer level instruments exploit Archimedes’ Principle to detect liquid level by continuously measuring the weight of an object (called the displacer) immersed in the process liquid. As liquid level increases, the displacer experiences a greater buoyant force, making it appear lighter to the sensing instrument, which interprets the loss of weight as an increase in level and transmits a proportional output signal.

Echo

|

| Radar level transmitter (Hawk). |

Weight

|

| Level can be determined by weight using load cells (BLH). |

Capacitive

Capacitive level instruments measure electrical capacitance of a conductive rod inserted vertically into a process vessel. As process level increases, capacitance increases between the rod and the vessel walls, causing the instrument to output a greater signal. Capacitive level probes come in two basic varieties: one for conductive liquids and one for non- conductive liquids. If the liquid in the vessel is conductive, it cannot be used as the dielectric (insulating) medium of a capacitor. Consequently, capacitive level probes designed for conductive liquids are coated with plastic or some other dielectric substance, so the metal probe forms one plate of the capacitor and the conductive liquid forms the other.

Radiation

Certain types of nuclear radiation easily penetrates the walls of industrial vessels, but is attenuated by traveling through the bulk of material stored within those vessels. By placing a radioactive source on one side of the vessel and measuring the radiation reaching the other side of the vessel, an approximate indication of level within that vessel may be obtained. Other types of radiation are scattered by process material in vessels, which means the level of process material may be sensed by sending radiation into the vessel through one wall and measuring back-scattered radiation returning through the same wall.

Power Specialties Sales Engineers are experts in industrial level control. Feel free to contact them at (816) 353-6550, or by visiting http://www.powerspecialties.com, for any level application. They'll assure you get the best continuous level control for the application.

Content above abstracted from “Lessons In Industrial Instrumentation”

by Tony R. Kupholdt under the terms and conditions of the

by Tony R. Kupholdt under the terms and conditions of the

Creative Commons Attribution 4.0 International Public License.

How Biofuels Are Produced

|

| From biomass to biofuels |

In the long run, we will need diverse technologies to make use of these different energy sources. Some technologies are already developed; others will be. Today, the most common technologies involve biochemical, chemical, and thermochemical conversion processes.

Ethanol, today’s largest volume biofuel, is produced through a biochemical conversion process. In this process, yeasts ferment sugar from starch and sugar crops into ethanol. Most of today’s ethanol is produced from cornstarch or sugarcane. But biochemical conversion techniques can also make use of more abundant “cellulosic” biomass sources such as grasses, trees, and agricultural residues.

Researchers develop processes that use heat, pressure, chemicals, and enzymes to unlock the sugars in cellulosic biomass. The sugars are then fermented to ethanol, typically by using genetically engineered micro- organisms. Cellulosic ethanol is the leading candidate for replacing a large portion of U.S. petroleum use.

A much simpler chemical process is used to produce biodiesel. Today’s biodiesel facilities start with vegetable oils, seed oils, or animal fats and react them with methanol or ethanol in the presence of a catalyst. In addition, genetic engineering work has produced algae with a high lipid content that can be used as another source of biodiesel.

Algae are a form of biomass which could substantially increase our nation’s ability to produce domestic biofuels. Algae and plants can serve as a natural source of oil, which conventional petroleum refineries can convert into jet fuel or diesel fuel—a product known as “green diesel.”

Researchers also explore and develop thermochemical processes for converting biomass to liquid fuels. One such process is pyrolysis, which decomposes biomass by heating it in the absence of air. This produces an oil-like liquid that can be burned like fuel oil or re ned into chemicals and fuels, such as “green gasoline.” Thermochemical processes can also be used to pretreat biomass for conversion to biofuels.

Another thermochemical process is gasification. In this process, heat and a limited amount of oxygen are used to convert biomass into a hot synthesis gas. This “syngas” can be combusted and used to produce electricity in a gas turbine or converted to hydrocarbons, alcohols, ethers, or chemical products. In this process, biomass gasifiers can work side by side with fossil fuel gasifiers for greater flexibility and lower net greenhouse gas emissions.

In the future, biomass-derived components such as carbohydrates, lignins, and triglycerides might also be converted to hydrocarbon fuels. Such fuels can be used in heavy-duty vehicles, jet engines, and other applications that need fuels with higher energy densities than those of ethanol or biodiesel.

Process Control Experts - Power Specialties, Inc.

Established in 1967, Power Specialties was founded on the concept that customer service is of primary importance. Our staff of Sales Engineers are well trained in the application and selection of instrumentation and control products. Specializing in providing instrumentation and control solutions for industry:

Visit http://www.powerspecialties.com or call (816) 353-6550.

- Ethanol / BioFuel

- Agricultural and Specialty Chemical

- Power

- Pharmaceutical

- Manufacturing

- Oil and Gas Production

Visit http://www.powerspecialties.com or call (816) 353-6550.

Magnetic Flowmeters: Principles and Applications

|

| Magnetic flowmeter (Yokogawa) |

In general, magnetic flowmeters are sturdy, reliable devices able to withstand hazardous environments while returning precise measurements to operators of a wide variety of processes. The magnetic flowmeter has no moving parts. The operational principle of the device is powered by Faraday's Law, a fundamental scientific understanding which states that a voltage will be induced across any conductor moving at a right angle through a magnetic field, with the voltage being proportional to the velocity of the conductor. The principle allows for an inherently hard-to-measure quality of a substance to be expressed via the magmeter. In a magmeter application, the meter produces the magnetic field referred to in Faraday's Law. The conductor is the fluid. The actual measurement of a magnetic flowmeter is the induced voltage corresponding to fluid velocity. This can be used to determine volumetric flow and mass flow when combined with other measurements.

The magnetic flowmeter technology is not impacted by temperature, pressure, or density of the subject fluid. It is however, necessary to fill the entire cross section of the pipe in order to derive useful volumetric flow measurements. Faradayís Law relies on conductivity, so the fluid being measured has to be electrically conductive. Many hydrocarbons are not sufficiently conductive for a flow measurement using this method, nor are gases.

Magmeters apply Faradayís law by using two charged magnetic coils; fluid passes through the magnetic field produced by the coils. A precise measurement of the voltage generated in the fluid will be proportional to fluid velocity. The relationship between voltage and flow is theoretically a linear expression, yet some outside factors may present barriers and complications in the interaction of the instrument with the subject fluid. These complications include a higher amount of voltage in the liquid being processed, and coupling issues between the signal circuit, power source, and/or connective leads of both an inductive and capacitive nature.

In addition to salient factors such as price, accuracy, ease of use, and the size-scale of the flowmeter in relation to the fluid system, there are multiple reasons why magmeters are the unit of choice for certain applications. They are resistant to corrosion, and can provide accurate measurement of dirty fluids ñ making them suitable for wastewater measurement. As mentioned, there are no moving parts in a magmeter, keeping maintenance to a minimum. Power requirements are also low. Instruments are available in a wide range of configurations, sizes, and construction materials to accommodate various process installation requirements.

As with all process measurement instruments, proper selection, configuration, and installation are the real keys to a successful project. Share your flow measurement challenges of all types with a process measurement specialist, combining your process knowledge with their product application expertise to develop an effective solution.

Labels:

flow measurement,

Instrumentation,

Iowa,

Kansas,

mag meter,

Magmeter,

magnetic flowmeter,

Missouri,

Nebraska,

Yokogawa

Yokogawa Smartdac+ Data Acquisition & Control for Paperless Recorders Type GX and GP

|

| Yokogawa Smartdac+ for GX/GP recorders |

In 2017, Yokogawa introduced Release 4 of the SMARTDAC+® GX series panel-mount type paperless recorder, GP series portable paperless recorder, and GM series data acquisition system.

With this latest release, new modules are provided to expand the range of applications possible with SMARTDAC+ systems and improve user convenience. New functions include sampling intervals as short as 1 millisecond and the control and monitoring of up to 20 loops.

For more information, visit Power Specialties here, or call (816) 353-6550.

Fieldbus Equipped Process Control Instrumentation: Part Two of Two

|

| (Image courtesy of Lessons in Industrial Instrumentation and Tony R. Kuphaldt and shared under Creative Commons 4.0 International Public License). |

Even in terms of the FOUNDATION instrumentation itself, there were two levels of networks being developed at this increased level of operation, initially: the first, H1, was considered low speed, while H2 was considered high speed. As the design process unfolded, existing Ethernet technology was discovered to fulfill the needs of the high speed framework, meaning the H2 development was stopped since the existing technology would allow for the H1 network to perform to the desired standards. The physical layer of the H1 constitutes, typically, a two-wire twisted pair ungrounded network cable, a 100 ohm (typical) characteristic impedance, DC power being conveyed over the same two wires as digital data, at least a 31.25 kbps data rate, differential voltage signaling with a defined threshold for both maximum and minimum peak receive rates, and Manchester encoding. Optical fiber can be used on some installations in lieu of the twisted pair cable.

Most of these specifications were exactly designed to withstand extremely challenging process control environments while still not abandoning the philosophy of being easy to build and implement, especially in terms of new system establishment. The most crucial aspects of many process control systems are streamlined together, allowing for consistent communication and synchronization. All aspects are viewable from both the legacy central controller and also via each individual device. Despite the data rate of 31.25 kbps being relatively slow, what is sacrificed in terms of speed is more than made up for in terms of the system being compatible with imperfect cables and other hiccups which may destabilize a network with faster speeds. The evolved technology, ease of installation, and durability have made the H1 network a widely used implementation of the FOUNDATION fieldbus technology. Fieldbus is currently considered one of a few widely adopted industrial process control communications protocols.

Contact Power Specialties with any process instrumentation, or field device communication question you may have. Visit http://www.powerspecialties.com or call (816) 353-6550.

Fieldbus Equipped Process Control Instrumentation: Part One of Two

|

| (Image courtesy of Lessons in Industrial Instrumentation and Tony R. Kuphaldt and shared under Creative Commons 4.0 International Public License). |

In a typical digital control system, dedicated controllers communicate with field instrumentation (the HART protocol is a prime example of digital communication at work in the industry). The host system controls configuration of instruments and serves as a central hub where all relevant control decisions are made from a single dedicated controller. Typically, these networks connect controllers and field devices through coupling devices and other "buses" which streamline many different instruments into a complete system.

FOUNDATION fieldbus approaches the same network scheme with an important difference. Whereas in a legacy or more conventional system, either algorithmic or manual decisions would need to be implemented via the dedicated system level controllers, instruments utilizing FOUNDATION fieldbus architecture can execute control algorithms at the local device level. The dedicated controller hub is still present, so that operators can view and monitor the entire network concurrently and make status changes. Algorithmic execution of control functions becomes entirely device reliant thanks to the FOUNDATION protocol. Additionally, even though FOUNDATION implements an advanced configuration, some operators use the capabilities introduced in the fieldbus upgrade to implement specific algorithms via each device while concurrently maintaining algorithms in the central controller. This dual algorithmic configuration allows for several advantages, including the ability for increased system precision.

Since individual devices in the control process are calibrated and able to execute their own control functions, issues in the process with particular devices can be isolated and dealt with in a more specified manner by technicians using the instruments in the field. The central operator retains the capacity to use the control hub to alter and direct the control system.

Stay tuned for Part Two.

Contact Power Specialties with any process instrumentation, or field device communication question you may have. Visit http://www.powerspecialties.com or call (816) 353-6550.

Labels:

communications,

FOUNDATION Fieldbus,

Instrumentation,

Iowa,

Kansas,

Missouri,

Nebraska,

networking

Introducing the Fox FT4A Thermal Mass Flow Meter

The Fox Model FT4A is the newest thermal gas mass flow meter offered from Fox Thermal Instruments.

The Model FT4A measures gas flow rate in standard units (SCFM, NM³/hr, LBS/HR, KG/HR & many more) without the need for temperature and pressure compensation.

A free software tool – FT4A View™ - is available for the Model FT4A that allows the user to connect to and configure the FT4A using a PC or laptop.

FEATURES:

The insertion flow meters have a 3/4" robust probe, are easy to install, and can be installed in pipe diameters of 1 1⁄2" to 70". Probe (I) and Retractor (R) sizes are: 6" (06I), 9" (09I), 12" (12I), 15" (15I/15R), 18" (18I/18R), 24" (24I/24R), 30" (30I/30R), and 36" (36I/36R).

The Display and Configuration Panel displays flow rate, flow total, elapsed time (hours since the totalizer was reset), process temperature and alarms. Field configurable variables include flow and temperature engineering units, 4 to 20mA scaling for flow and temperature, standard temperature and pressure (STP), pulse output scaling, zero flow cut off, alarm settings (high flow, low flow, high temp, and low temp), filter setting, and many others.

The Fox Calibration laboratory uses NIST traceable flow standards to ensure the highest level of accuracy. A calibration certificate is supplied with every meter.

The discrete output can be set to provide a signal when alarms are generated.

For more information on the FT4A contact Power Specialties at (816) 353-6550 or visit this link for the Power Specialties website.

The Model FT4A measures gas flow rate in standard units (SCFM, NM³/hr, LBS/HR, KG/HR & many more) without the need for temperature and pressure compensation.

A free software tool – FT4A View™ - is available for the Model FT4A that allows the user to connect to and configure the FT4A using a PC or laptop.

FEATURES:

Direct Mass Measurement

The Fox Model FT4A measures the mass flow of gases directly in Standard Cubic Feet per Minute (SCFM), Normal Cubic Meters per Hour (NM³/hr), Kilograms per Hour (Kg/Hr), and other mass units without the need for pressure or temperature compensation. One isolated 4 to 20mA output programmable for flow or temperature is standard; HART communication optional. A second output is selectable for pulse or RS485 Modbus RTU.Outstanding Low Flow Capability, Wide Turn-Down Ratio

The Fox flowmeter is capable of providing precise measurement of extremely low velocity gas flows. This results in a wide measurement range and a turn down ratio up to 1000:1; 100:1 typical.DDC-SensorTM

The non-cantilevered design of the DDC-SensorTM is standard on all Model FT4A flowmeters. Instead of using traditional analog circuitry, the DDC-SensorTM is interfaced directly to the FT4A microprocessor for more speed and programmability.Gas-SelectX®

The Model FT4A has many common gas calibrations pre-programmed into the meter so that the user can select a gas from a list to fit the application. Three gas menus are available: Pure Gas Menu, Mixed Gas Menu, and Oil & Gas Menu.

Probe and Retractor Sizes

The insertion flow meters have a 3/4" robust probe, are easy to install, and can be installed in pipe diameters of 1 1⁄2" to 70". Probe (I) and Retractor (R) sizes are: 6" (06I), 9" (09I), 12" (12I), 15" (15I/15R), 18" (18I/18R), 24" (24I/24R), 30" (30I/30R), and 36" (36I/36R).

Field-Programmable

The Display and Configuration Panel displays flow rate, flow total, elapsed time (hours since the totalizer was reset), process temperature and alarms. Field configurable variables include flow and temperature engineering units, 4 to 20mA scaling for flow and temperature, standard temperature and pressure (STP), pulse output scaling, zero flow cut off, alarm settings (high flow, low flow, high temp, and low temp), filter setting, and many others. Digital Communications / FT4A ViewTM

Bus options are RS485 Modbus RTU and HART. The FT4A uses a standard USB port to connect to a PC. Fox's free FT4A ViewTM software provides complete configuration and remote process monitoring functions.

NIST Traceable Calibration

The Fox Calibration laboratory uses NIST traceable flow standards to ensure the highest level of accuracy. A calibration certificate is supplied with every meter.

Discrete Output

The discrete output can be set to provide a signal when alarms are generated.Enclosure and Area Rating

NEMA 4X enclosure approved for FM and FMc Class I, Division 1; ATEX/IECEx Zone 1 approved. CE mark.Input Power

Input Power: 12 to 28VDC, 20 watts max. Full Input Power Range: 10 to 30VDC, 20 watts max.For more information on the FT4A contact Power Specialties at (816) 353-6550 or visit this link for the Power Specialties website.

Labels:

Fox Thermal Instruments,

gas flow,

Iowa,

Kansas,

Missouri,

Nebraska,

thermal mass flow meter

Power Specialties: Industrial Markets

Established in 1967, Power Specialties was founded on the concept that customer service is of primary importance. Our staff of Sales Engineers are well trained in the application and selection of instrumentation and control products. Specializing in providing instrumentation and control solutions for industry:

- Ethanol / BioFuel

- Agricultural and Specialty Chemical

- Power

- Pharmaceutical

- Manufacturing

- Water/Wastewater

- Food/Beverage

- Oil and Gas Production

For more information, visit Power Specialties at http://www.powerspecialties.com or call (816) 353-6550 .

Rotary and Linear Damper Drives for Control of Combustion Air and Flue Gas

|

| Electric Damper Drive (Rotork) |

Damper Operator (Drives) Types :

Damper drives can be one of three types: pneumatic, electric, or electro-hydraulic, as described below.

A very important part of damper design is determination of damper torque and sizing and selection of damper actuator for the maximum torque. Actuator torque should be selected to provide the maximum torque required to operate the damper as well as to provide margin and allow for degradation over the life of the damper. Actuators should be evaluated for damper blade movement in both directions, at the beginning of blade movement, and while stroking blades through the full cycle of movement.

The Goal for Selecting the Best Drive Technology:

Reduced emissions, lower fuel consumption and improved boiler draft control.

Ways to achieve this goal:

- Pneumatic. These damper operators are used whenever controls rely primarily on compressed air (pneumatic) for moving operators.

- Electric. These damper operators are used whenever controls rely primarily electricity as the power source.

- Electro-hydraulic. These damper operators are the same as the electric type described above, but also have a hydraulic system to position the damper.

|

| Pneumatic Damper Drive (Rotork Type K) |

The Goal for Selecting the Best Drive Technology:

Reduced emissions, lower fuel consumption and improved boiler draft control.

Ways to achieve this goal:

|

| Installed Damper Drive |

- High speed continuous modulation of ID/FD fan and inlet guide vanes

- Improved modulation and control of secondary air dampers

- Improved automation and burner management

- Quick response to plant demand

- Improved reliability in high temperature environments

- Precise damper and burner positioning

- Simple commissioning and diagnostics

- Low running costs, virtually maintenance free

- Pneumatic, analog and bus network communications

For more information, review the document below, or download it at this link on Power Specialties website.

Basics of Pressure Measurement: Hydrostatic Pressure

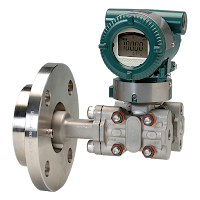

|

| Pressure transmitter (Yokogawa) |

A common method for measuring hydrostatic pressure is a simple gauge. The gauge is installed at the bottom of a vessel containing a column of liquid and returns a measurement in force per unit area units, such as PSI. Gauges can also be calibrated to return measurement in units representing the height of liquid since the linear relationship between the liquid height and the pressure. The particular density of a liquid allows for a calculation of specific gravity, which expresses how dense the liquid is when compared to water. Calculating the level or depth of a column of milk in a food and beverage industry storage vessel requires the hydrostatic pressure and the density of the milk. With these values, along with some constants, the depth of the liquid can be calculated.

The liquid depth measurement can be combined with known dimensions of the holding vessel to calculate the volume of liquid in the container. One measurement is made and combined with a host of constants to determine liquid volume. The density of the liquid must be constant in order for this method to be effective. Density variation would render the hydrostatic pressure measurement unreliable, so the method is best applied to operations where the liquid density is known and constant.

Interestingly, changes in liquid density will have no effect on measurement of liquid mass as opposed to volume as long as the area of the vessel being used to store the liquid remains constant. If a liquid inside a vessel that’s partially full were to experience a temperature increase, resulting in an expansion of volume with correspondingly lower density, the transmitter will be able to still calculate the exact mass of the liquid since the increase in the physical amount of liquid is proportional to a decrease in the liquid’s density. The intersecting relationships between the process variables in hydrostatic pressure measurement demonstrate both the flexibility of process instrumentation and how consistently reliable measurements depend on a number of process related factors.

Interestingly, changes in liquid density will have no effect on measurement of liquid mass as opposed to volume as long as the area of the vessel being used to store the liquid remains constant. If a liquid inside a vessel that’s partially full were to experience a temperature increase, resulting in an expansion of volume with correspondingly lower density, the transmitter will be able to still calculate the exact mass of the liquid since the increase in the physical amount of liquid is proportional to a decrease in the liquid’s density. The intersecting relationships between the process variables in hydrostatic pressure measurement demonstrate both the flexibility of process instrumentation and how consistently reliable measurements depend on a number of process related factors.

Contact Power Specialties at (816) 353-6550 or visit http:powerspecialties.com with any industrial pressure measurement application of requirement.

Happy Fourth of July from Power Specialties

"We hold these truths to be self-evident, that all men are created equal, that they are endowed by their Creator with certain unalienable Rights, that among these are Life, Liberty and the pursuit of Happiness. — That to secure these rights, Governments are instituted among Men, deriving their just powers from the consent of the governed, — That whenever any Form of Government becomes destructive of these ends, it is the Right of the People to alter or to abolish it, and to institute new Government, laying its foundation on such principles and organizing its powers in such form, as to them shall seem most likely to effect their Safety and Happiness."

THOMAS JEFFERSON, Declaration of Independence

THOMAS JEFFERSON, Declaration of Independence

Proper Wiring of Yokogawa ROTAMASS with Remote Converter

|

| Yokogawa ROTAMASS with remote converter. |

The ROTAMASS is available in two designs - an integral converter and a remote converter.

When working with the remote design, it's important to wire the remote converter to the flow tube properly to avoid signal error and faulty readings. The video below carefully explains the proper way to wire the two components together.

For any Yokogawa instrumentation requirement in Kansas, Nebraska, Iowa, or Missouri, contact Power Specialties. Visit http://www.powerspeciaties.com or call (816) 353-6550.

Rotary Drives for Industrial Damper and Louver Applications

|

| Type K damper drives. |

- Drop-In-Place retrofit requires no field engineering or fabrication

- Improved reliability in high temperature environments

- Rated for 100% duty-cycle, continuous modulating service

- Highly accurate to 0.25% resolution

- Discrete contacts (O/C) and pneumatic, analogue or bus network (MOD) communications

Visit this link for more information on rotary drives or contact Power Specialties at (816) 353-6550.

Subscribe to:

Posts (Atom)